The contact type segment of the position sensor market is bifurcated into contact and non-contact. Under this segment, the contact category accounted for a larger market share in 2018, on account of the lower cost of contact position sensors than non-contact variants. The lower cost of these sensors makes them quite popular among developing countries, such as China, India, and Indonesia.

Whereas, the non-contact category is expected to witness faster growth during the forecast years, owing to the higher accuracy of non-contact position sensors in nanometer and sub-micron levels. These sensors are manufactured by MEGATRON Elektronik GmbH & Co. KG., Renishaw plc, MTS Systems Corporation, TE Connectivity Ltd., Infineon Technologies AG, ams AG, Sensata Technologies Inc., SICK AG, Bourns Inc., and Honeywell International Inc.

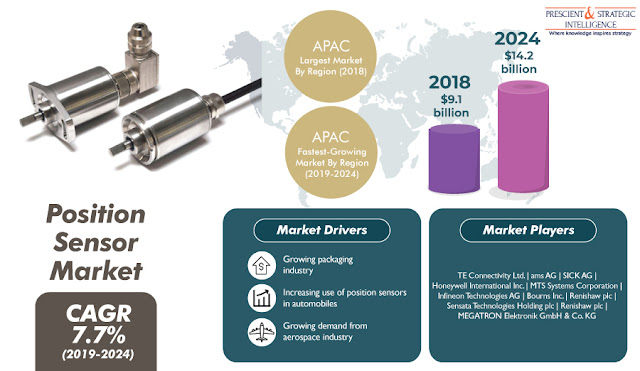

In recent years, these companies have primarily focused on product launches to cater to the needs of the end-use industries. For example, in 2018, ams AG introduced AS5200L, a magnetic rotary position sensor with an inter-integrated circuit (I2C) interface to develop safety-critical vehicle applications. Geographically, the Asia-Pacific (APAC) region accounted for the largest share in the position sensor market in 2018, and it is also projected to display the fastest growth in the forecast years.

The growth of the APAC market can be attributed to the soaring demand for consumer electronics and vehicles in the regional countries, owing to the growing population and mounting disposable income of people. In addition, the rising EV production and adoption, on account of the soaring air pollution levels and mounting government support toward the EV industry, will also catalyze the market growth in the region.

Therefore, the expanding automotive sector and the booming packaging sector will facilitate the adoption of position sensors in the forthcoming years.

Whereas, the non-contact category is expected to witness faster growth during the forecast years, owing to the higher accuracy of non-contact position sensors in nanometer and sub-micron levels. These sensors are manufactured by MEGATRON Elektronik GmbH & Co. KG., Renishaw plc, MTS Systems Corporation, TE Connectivity Ltd., Infineon Technologies AG, ams AG, Sensata Technologies Inc., SICK AG, Bourns Inc., and Honeywell International Inc.

In recent years, these companies have primarily focused on product launches to cater to the needs of the end-use industries. For example, in 2018, ams AG introduced AS5200L, a magnetic rotary position sensor with an inter-integrated circuit (I2C) interface to develop safety-critical vehicle applications. Geographically, the Asia-Pacific (APAC) region accounted for the largest share in the position sensor market in 2018, and it is also projected to display the fastest growth in the forecast years.

The growth of the APAC market can be attributed to the soaring demand for consumer electronics and vehicles in the regional countries, owing to the growing population and mounting disposable income of people. In addition, the rising EV production and adoption, on account of the soaring air pollution levels and mounting government support toward the EV industry, will also catalyze the market growth in the region.

Therefore, the expanding automotive sector and the booming packaging sector will facilitate the adoption of position sensors in the forthcoming years.

Comments

Post a Comment